In order to check water resistance of a watch we use pressure testing equipment. In our workshop we use two different types – a “dry” tester and a “wet” tester. In this blog post we’ll discuss using the wet pressure tester and how this is used to help us check a watch case for any leaks.

As the name would suggest the “wet” tester involves immersing the watch in water. The steps involved in testing a watch are broadly outlined below.

Firstly, it should be said we test the watch case without the movement. While in theory this precaution is not necessary (it will become clear why), we prefer to absolutely err on the side of caution. As such, the movement is removed from the case. We then re-assemble the case, so it is complete with crown and case back.

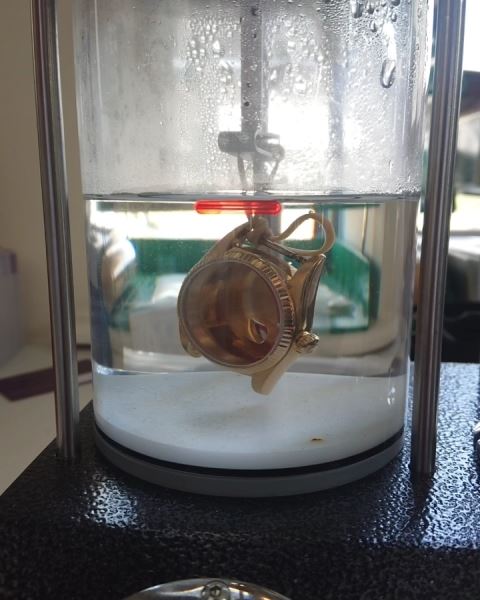

Now we have a case ready to put in the pressure tester, The case is loaded into the machine and suspended from a hook. We now need to seal the machine – tightening the retaining bolts and making sure the pressure release valve is closed.

Next, it’s time to pressurise the chamber. Our testing machine uses a manual pump, so we repeatedly pull the lever and pressurise the chamber until it reaches the level of pressure, we’re testing this specific watch to.

Once the chamber is pressurised it’s important to wait for a while. This allows the pressure in the chamber and inside the watch to equalise if there’s a leak. The case is then carefully lowered into the water. Once in the water we slowly release the pressure release value.

If there’s a leak in the case, the case will have pressurised to the same level as the air. This means as the pressure in the chamber begins to be lowered, a stream of bubbles begins to appear from the source of the leak. Here you can see why in theory a watch could be tested complete – if the pressure is higher inside the watch, air will be pushed out rather than water allowed in. If there is no leak, we do not see any streams of bubbles as the pressure inside the case remains at the level it was before going into the tester – 1 atmosphere.

Once confident in the result, the watch is lifted from the water before all the pressure in the chamber is released. When the pressure is fully released the watch case can be retrieved from the machine and dried off.

As you can see, use of this machine is very important. It helps with diagnosing the location of faulty seals, and also means we are able to say the case has been tested as properly water resistant, as opposed to if we solely used the air tester. Once the case is dry the movement is reinstalled and we then finish the job off by using our “dry” testing machine on the complete watch.

Do you have a watch in need of repair? Contact us and see how we can help. We are experts in the repair of watches both modern and vintage. We offer a fully insured freepost repairs service and as business partners of the British Horological Institute, as well as holders of a Feefo Platinum Service Award, you can be confident when dealing with us.

Please Contact Us for further information regarding any requirement you may have.

Yours sincerely

David Clark DGA PJDip PJGemDip CertGA

Managing Director

W.E. Clark & Son Limited