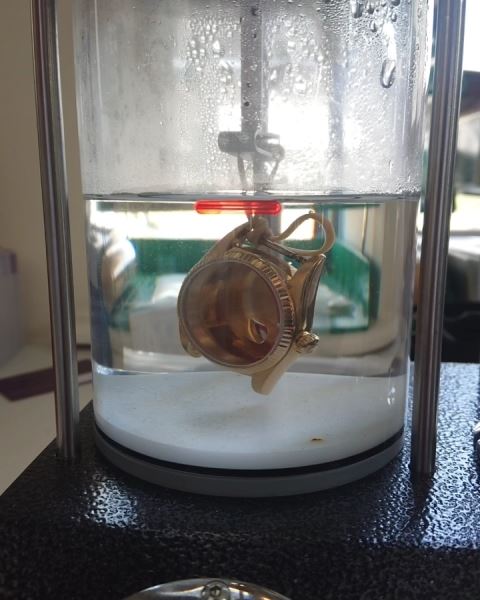

Water damaged watches are all too common, and we see them quite regularly in our workshop. Depending on the type of watch and the severity of the damage, water ingress can lead to a hefty repair bill. But why does water damage happen in the first place? And what should you do if the worst does happen? We’ll attempt to briefly answer the first of these questions in this two part blog post..

Watches labelled as water resistant are just that – water resistant, rather than waterproof (and if they’re labelled “waterproof” this is often erroneous). Each watch has a different level of water resistance, ranging from not at all and splashproof through to 50m, 100m, 200m and even more. These ratings mean your watch can handle being exposed to this level of use in water. There is often some confusion caused by the labelling of these ratings, as it is not as clear cut as 50m = it can be used in water to depths of 50m. Here’s our guide to the common ratings:

No labelling on case or dial: Not resistant to splashing or contact with moisture of any kind.

Water-resistant: 30M / 100Ft / 3ATM / 3Bar: Will resist moisture from accidental splashing, rain, sweat etc. Not suitable for immersion.

Water-resistant 50M / 160Ft / 5ATM / 5Bar: Will resist moisture from accidental splashing, rain, and showering or swimming.

Water-resistant 100M / 300Ft / 10ATM / 10Bar: Watch may be worn during swimming, snorkelling and skin diving, if properly sealed.

Water-resistant: 200M / 660Ft / 20ATM / 20Bar: Watch may be worn during standard scuba diving.

Water-resistant: 300M / 1000Ft / 30ATM / 30Bar: Watch may be worn during scuba diving and saturation diving.

It may be your watch has been exposed to water at above and beyond it’s rating, causing one of the seals to fail. Seals may also fail for other reasons – they’re often made of rubber, which is perishable. Rubber seals need replacing every so often. They also need to be kept clean and seated properly. If you have your watch regularly serviced the seals can be assessed and changed as required – another reason not to skip on that maintenance service just because your watch appears to be running well at the moment.

Water damage may also occur due to human error. If your watch has a screw-down crown, this needs to be screwed down for the watch to be sealed and thus water resistant. If you have a chronograph watch, pushers should not be pressed when the watch is immersed in water as this may again compromise the seal. Damage to the glass can allow water to leak into the case through the front. All of these are examples of user error and would not be covered under any sort of a guarantee.

In part two of this blog post we’ll discuss what to do if the worst does happen, as well as look at what not to do! Look out for part two coming soon.

Yours sincerely

David Clark DGA PJDip PJGemDip CertGA

Managing Director

W.E. Clark & Son Limited