One popular service we offer in our workshop is the polishing and refinishing of the case and bracelet of a watch. This involves using a selection of different polishing mops, wheels and compounds to restore the finish of your watch back to a good standard.

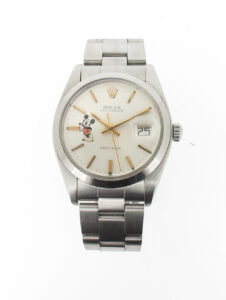

A recent job involved doing just this to a Rolex Explorer watch. This watch didn’t look like it had seen particularly heavy wear, so in these instances it is possible to achieve an excellent standard of finish. Were, for example, the watch to be heavily dented and scratched, a certain level of realistic expectations would be required as the refinishing work would be a compromise between maintaining the shape and dimensions of the case vs removing all of the various dents and scratches.

The first step was to remove the movement from the case. Once the movement is removed we can disassemble the case – so this means removing the bezel, glass and case tube. Once the case is down to its individual components, we are able to give everything a clean before we begin the polishing process.

The refinishing process involves progressively polishing the different elements of the case using a few different techniques. This is all done using our Twin-Spindle polishing machine. Our preference is to use Menzerna polishing compounds, though there are other manufacturers who offer comparable products. We also need to apply a grained finish to parts like the bracelet. This is done with a Bergeon graining wheel of the correct type to match the original finish.

Once the refinishing of each part of the case and bracelet are complete, they are given an ultrasonic clean. Each part is then steam cleaned to ensure everything is spotless before reassembly.

Reassembling the case is a matter of initially refitting the case tube and glass, before then fitting the friction fit bezel. Once this is done the movement can be re-installed into the case, before the case back is fitted and the watch tested for water resistance. The watch is also checked on our timegrapher to confirm the timekeeping is still excellent. We now refit the bracelet. Once fully reassembled, this watch is ready for testing before release to our client.

Yours sincerely

David Clark FGA DGA MJVA PJDip. PJGemDip.

Managing Director, JVA Registered Valuer®

W.E. Clark & Son Limited