Patek Philippe is a name synonymous with luxury, precision, and craftsmanship. Patek has a storied history spanning over 180 years. Founded in 1839 by Antoine Norbert de Patek and François Czapek in Geneva, Switzerland, the company has become one of the most prestigious and sought-after watchmakers in the world.

The early years of Patek Philippe were marked by the partnership between de Patek and Czapek. However, in 1844, Adrien Philippe, a French watchmaker, joined the company, and the brand evolved into Patek Philippe & Co. In 1851, Czapek left the company, leaving the stage for the iconic partnership between Patek and Philippe. This partnership laid the foundation for the brand’s commitment to innovation and excellence.

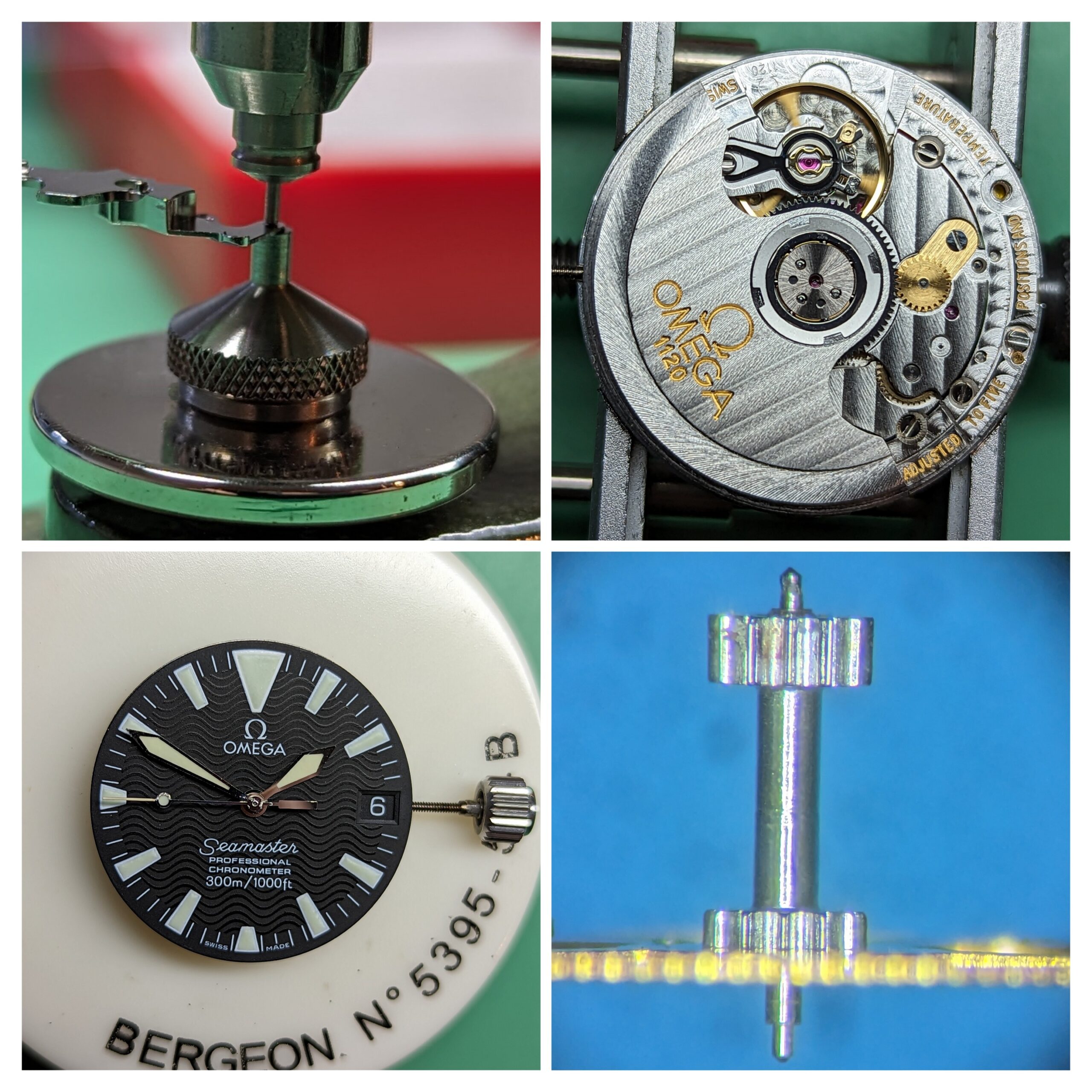

One of Patek Philippe’s groundbreaking inventions during this period was the keyless winding system, patented by Adrien Philippe in 1845. This revolutionary innovation eliminated the need for a key to wind the watch, paving the way for the development of modern winding mechanisms. The keyless winding system became a hallmark of Patek Philippe watches and set the brand apart from its competitors. Philippe received a coveted Bronze Medal for his inventions at the Industrial Exposition in Paris.

In 1868, Patek Philippe achieved another significant milestone by creating the first Swiss wristwatch, commissioned by Countess Koscowicz of Hungary. This early wristwatch was a bracelet watch with a baguette-shaped movement, demonstrating the brand’s commitment to pushing the boundaries of watchmaking.

The late 19th and early 20th centuries witnessed Patek Philippe’s participation in various international exhibitions, where the brand consistently received accolades for its precision and innovation. The company also established itself as a favourite among royalty and dignitaries, further cementing its reputation for producing timepieces of unparalleled quality and craftsmanship.

The Great Depression and the two World Wars presented challenges for many industries, but Patek Philippe weathered these storms with resilience. The brand continued to innovate, introducing the Calatrava collection in 1932, which remains one of its most iconic and enduring lines.

Also during this period the Stern family, who had been dial suppliers for Patek Philippe, acquired the company. The Sterns brought stability and a renewed focus on the brand’s heritage, guiding Patek Philippe through the post-war era and into the modern age.

The latter half of the 20th century saw Patek Philippe continuing to innovate with numerous interesting models and movements, including the development of the ultra-thin Caliber 240 in 1977.

Patek Philippe’s commitment to uncompromising quality is epitomised by its adherence to the Patek Philippe Seal – a set of strict self-imposed quality standards. Each Patek Philippe timepiece is a work of art, created by master craftsmen using traditional techniques combined with cutting-edge technology.

Today, Patek Philippe watches are considered not just timepieces but also symbols of prestige and exclusivity. The brand’s commitment to innovation, precision, and timeless design has made it a favourite among collectors and connoisseurs, ensuring that the legacy of Patek Philippe will continue for generations to come.

Yours sincerely

David Clark FGA DGA MJVA PJDip. PJGemDip.

Managing Director, JVA Registered Valuer®

W.E. Clark & Son Limited